Introduction

Skilled Shun artisans produce blades of unparalleled quality and beauty.

This beautiful Japanese top-end range is handmade and we have been selling Shun knives for many, many years along with electric Shun sharpeners and whetstones, guards and rolls.

Building on the ancient skills of Japan’s swordsmiths, and combining this experience with cutting-edge technology, each Shun knife is handcrafted and requires at least 100 steps to complete. It doesn’t come as a surprise that KAI Shun knives are admired and desired all over the world.

Shun History

In 1908 Kai Corporation started life as a small pocket knife manufacturer in Seki, the ancient sword-making capital of Japan. Today Kai manufactures, sells, exports and imports more than 10,000 different types of cutlery and cutting tools, ranging from kitchen utensils to cosmetic accessories and surgical implements. The tradition and skills handed down from the sword-smiths of ancient Japan have always been an inspiration and integral part of every Kai product since the company’s foundation.

Similarly, Kai Shun kitchen knives are made using a combination of state of the art technology and long experience, and are highly esteemed all over the world – each Shun knife is handcrafted in Japan and requires at least 100 meticulous steps to complete.

Handcrafted in Japan it takes more than 100 steps to make each Shun knife.

In Japan, the blade has long been more than just a tool; the way of the blade is a way of life.

In Japanese, “Shun” (pronounced “shoon” and rhymes with “moon”) is the precise moment during the year when any particular food is at the peak of its perfection. Shun is when the fruit is at its sweetest when vegetables are perfectly ripe, perfectly fresh, and perfectly delicious. Shun is in harmony with the natural rhythms of the seasons. Kai Shun knives proudly take their name from this Japanese culinary tradition of preparing and eating the very freshest food at the perfect “shun” moment. It is a tradition we live up to every day, making fine kitchen knives that are always at the peak of their perfection, too.

In the spirit of the legendary sword smiths of Japan

From the legendary samurai swords said to contain the soul of the warrior who wielded them to the handcrafted kitchen knives of today, the exquisite craftsmanship of Japanese blades is admired worldwide. Since the 13th century, Seki City has been the heart of the Japanese cutlery industry. For more than 100 years, it has also been home to the Kai Corporation, the makers of Kai Shun fine knives. Inspired by the blade-making traditions of ancient Japan, today’s high.

Blades Features Chart

Browse Shun Knives Ranges

SHUN PREMIER

Shun Premier calls to mind the handcrafting techniques of ancient Japan yet offers performance born from the latest advances in knife design and technology.

Premier blades are thinner and lighter for fast and agile handling, while the blade design – with wide weight distribution from the tip to end cap – ensures stability and strength.

Shun Premier blades are made of VG-MAX steel, clad with stainless Damascus. Where the steels meet, an attractive wavy line called a hamon is formed. Premier blades are ground to a quick taper edge that helps move food away from the blade quickly. The beautiful hand-hammered finish – tsuchime (tsoo-CHEE-may) in Japanese – also improves food release when cutting. The two-position handle, in rich walnut PakkaWood, offers a trigger grip for pull cuts as well as the perfect balance point for a pinch grip.

Features:

- NSF Certified for use in commercial kitchens.

- limited warranty from manufacturing defects.

- Blade Material Proprietary VG-MAX hardened Japanese steel cutting core, each side with 34 layers (69 total including core) of SUS410/SUS431 pattern stainless steel Damascus cladding

- Cutting Edge Hand-sharpened 16° double-bevel blade

- Hardness 60 HRC

- Blade Finish Hammered tsuchime finish helps release food easily when cutting

- Handle Material Contoured, ambidextrous walnut coloured PakkaWood (premium, resin-impregnated hardwood)

SHOP SHUN PREMIER Knives

SHUN CLASSIC

Shun Classic is the perfect line for those making their first foray into the Japanese knife market.

Produced in the widest variety of specialised styles, the Classic line features both traditional European blade shapes and innovative cutting-edge designs.

Handcrafted in Japan it takes more than 100 steps to make each Shun knife. Born of the ancient samurai swordmaking tradition and hand-finished for precision and beauty, the Shun Classic series features beautiful Damascus-clad blades and D-shaped ebony PakkaWood handles. Yet behind these handcrafted knives’ beauty is function; razor-sharp blades offer top performance. Shun Classic’s proprietary high-performance VG-MAX steel, which provides incredible edge retention, is clad with 34 layers of Damascus stainless steel on each side (a total of 69 layers), then ground and bead-blasted, revealing the flowing pattern of the layered steel.

The result is a line of knives that are sharp, durable, and corrosion resistant, as well as beautiful to behold.

Features:

- NSF certified for commercial kitchens.

- Blade Material VG-MAX hardened Japanese steel cutting core, each side clad with 34 layers (total 69 layers of steel) of SUS410/SUS431 Pattern Damascus stainless steel.

- Cutting Angle Double bevelled 16° cutting angle each side.

- Hardness 60 HRC.

- Handle Material The D-shaped ebony coloured PakkaWood (premium, resin-impregnated, moisture-resistant hardwood) handle is designed to comfortably sit in your hand.

SHOP SHUN CLASSIC Knives

SHUN SORA

In Japanese, Sora means “sky”.

With Sora’s proprietary Composite Blade Technology, this beautiful series offers sky-high value by bringing together a VG10 three-layer San Mai cutting edge with a polished Japanese 420J stainless steel upper. This technology puts high-performance material exactly where it’s needed most, on the cutting edge.

The two blade sections are laser cut, then fit together like pieces of a jigsaw puzzle. Braze welding permanently joins them. The attractive wavy pattern at the joint is based on traditional Japanese sword hamon lines.

While Sora’s blade shapes and handle design are traditional Japanese, the textured PP/TPE polymer blend handle material provides a contemporary look, secure grip and balance, and is easy to maintain.

Features:

- Blade Material VG10 is clad with one layer of stainless steel on each side to create the san mai edge and provide stain resistance. Mirror-polished Japanese 420J blade upper. Featuring a modern ‘hamon’ design.

- Cutting Angle Double bevelled 16° cutting angle on each side.

- Hardness 60 HRC.

- Handle Material Traditional handle design in easy-care textured TPE/PP blend. Featuring Shun’s signature emblem. Rabbet tang.

SHOP SHUN SORA KNIVES

SHUN KANSO

If you have admired the simple lines and effortless grace of Japanese design, you have experienced kanso.

Kanso is a design principle based on Zen philosophy. It means “simplicity”, but simplicity that is achieved by eliminating the non-essential.To create Shun Kanso, Kai Shun has taken away anything that doesn’t matter and kept everything that does; high-performance steel, razor-sharp edge, with full tang construction providing the perfect balance and precision cutting control.

The steel is Japanese AUS10A—highly refined, high-carbon, vanadium stainless steel that takes a razor-sharp edge and holds it longer. Kanso’s Heritage finish hides scratches and gives Kanso a rustic look that just improves with age. The handle is made of tagayasan wood, sometimes known as “iron sword wood.”

The handle contouring enables an easy chef’s grip. Full-tang construction provides strength, balance, and easy cutting control. Like all Shun knives, Kanso is sharpened to a 16° cutting angle on each side to cut cleanly and help preserve food’s freshness and best taste.

Kanso is a simple and beautiful kitchen knife with a rustic, heritage finish that performs every time.

Features:

- Blade Material Japanese AUS10A blade steel – highly refined, high-carbon, vanadium stainless steel that takes a razor-sharp edge and holds it longer.

- Cutting Angle Double bevelled 16° cutting angle each side.

- Handle Material Contoured tagayasan wood handle – known as “iron sword wood”, tagayasan is dense, durable and beautiful.

SHOP SHUN KANSO Knives

SHUN KAI BENIFUJI

Kai Benifuji is part of the Seki Magoroku range of knives.

Many celebrated swords were born in Seki area and in the Kamakura era. The master craftsman “Magoroku of Seki” had the original technique producing beautiful swords which were high quality and had outstanding sharpness. Made in Japan, these knives have a full tang which makes them robust and eases hand fatigue. Constructed from AUS-8A stainless steel, each blade is subjected to a 3 chamfering processes. This special grinding process reduces the friction against food and blade and gives you a knife with an extremely sharp cutting edge.

Like others in the Kai family, the handle is made from hard-wearing PakkaWood which enables durability and comfort, as well as making it an attractive looking knife to have in your collection.

Features:

- Blade Material Full tang, Japanese AUS-8A blade steel

- Cutting Angle Double bevelled 16° cutting angle each side.

- Hardness 60 HRC.

- Handle Material PakkaWood (premium, resin-impregnated hardwood)

SHOP KAI BENIFUJI Knives

Shun Knives Use & Care

Japanese knives are very different from strong German blades.

They can be sharper but need to be treated with respect since they are things of beauty and delicate. Here are a few tips to get the most out of your Shun knife.

- How to CUT with a Shun knife. Shun knives are designed to use in a ‘locomotive’ motion rather than a forceful ‘chopping’ manner. If you push the knife forward and down while cutting, then pull it up and back towards you, you’ll find this is practically effortless!

- FOODS to cut with Shun. Never cut frozen food with a Shun knife as this could damage the delicate blade. Shun knives are designed for cutting meat and veg rather than bones or even very thick-skinned vegetables like pumpkins.

Cleaning & Storing your Shun Knife

As with any lifetime investment, it is important to take the best care possible in order to prolong the life of your Shun knife.

Before using Shun knives for the first time clean them with hot water. After each use clean them under running water and dry them with a soft cloth; do not use aggressive detergents.

- For your own safety, you should always wipe the knife with a towel or cloth from the blade’s back towards the edge.

- Rinse off aggressive agents like lemon juice directly after use. Shun recommends that you protect your investment by handwashing your blades with gentle dish soap.

- Do not use soaps with citrus extracts; they can promote rust.

- Do not use scouring pads, steel, or gritty cleanser when cleaning the blades.

- Rinse and towel dry immediately. Let the knives air dry for a few minutes before returning them to storage.

- Never leave your knife sitting in a sink full of soapy water, metal does not respond well to being submerged in water for prolonged periods of time. Micro-corrosion, which can result in tiny chips or missing pieces in your knife’s cutting edge, can occur because moisture is left on the cutting edge. Moisture weakens the stainless steel and promotes micro-corrosion. If moisture is left on the cutting edge repeatedly, even normal use in the kitchen can result in small chips in the weakened sections of the edge. To guard against this, wash your knife immediately after use and dry it very thoroughly with an absorbent cloth or towel. Please take extra care to safely dry the sharp cutting edge of your Shun, keeping your fingers away from the edge.

- After you have washed and dried your knives, store them in a block, knife case, in-drawer tray, sheath or wooden magnetic knife holder. We do not recommend storing the knives unsheathed in a drawer, as this can be a potential hazard to the blades as well as your fingers.

Note: Handwashing is also the best way to care for the wood handles of your Shun knives. Although the wood has been stabilized, it is natural wood and, like all wood, will tend to shrink in very arid environments and swell in very humid environments. The handle colour may change slightly over time due to oils in the hand as well as the natural colour change of wood from oxidation and/or exposure to light. This is not a defect, but a natural part of the process.

Sharpening & Honing

Shun quality knives need a certain amount of care so that you can enjoy your sharp knife for years to come.

Never cut on glass or granite cutting boards. These may be easy to clean but will ruin the edge of even the hardest steel. Use only wooden boards, wood composite or synthetic cutting boards of medium firmness. When using, always ensure the blade does not strike hard materials. The blade can be damaged when cutting around bones, frozen foods, thick-skinned vegetables like butternut squash or other hard objects. Occasionally oil the handle with neutral vegetable oil.

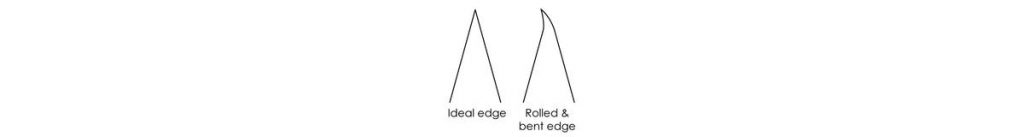

Honing versus Sharpening

In order to maximize the life of the blade, regular honing with a Shun steel will be necessary. Sharpening is the act of taking metal off the blade in order to improve the sharpness, this should only need to be done occasionally depending on how often you use and how you care for your knives.

However, weekly honing is wise and will extend the time between sharpening significantly. Honing is the process of realigning the blade’s edge to ensure it remains sharp.

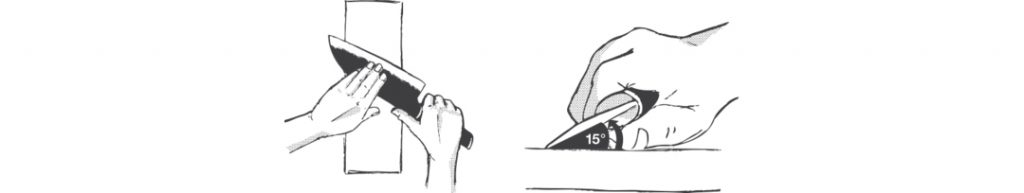

Simply hold your honing steel vertically, placing the tip of your steel on your chopping board. Starting at the heel and at the top of the steel, draw the knife down the steel, running from the knife heel to the tip. Repeat this at the top of the steel with your knife and run your knife in downward motions at about a 16° angle. Make sure to do alternate sides for a double-bevelled blade and to hone the full length of the blade. Simply wash with warm water and dry thoroughly after honing.

When the time comes to sharpen these premium blades, we recommend using a whetstone, the electric sharpener (specifically designed to sharpen Shun’s 16° blade angle), or sending the knives to a professional sharpener.

Whetstones

What Grit Whetstone is Best?

Typically a coarse whetstone, 300 grit or so, will remove material quickly. This is useful for repairing chips or other imperfections. A medium grit whetstone, typically 1000 to 1500, is suitable for sharpening most knives that have a blade in reasonable but dull condition. A fine to a very fine whetstone, around 4,000 to 6,000 grit is used for finishing and polishing your blade to a mirror-like finish.

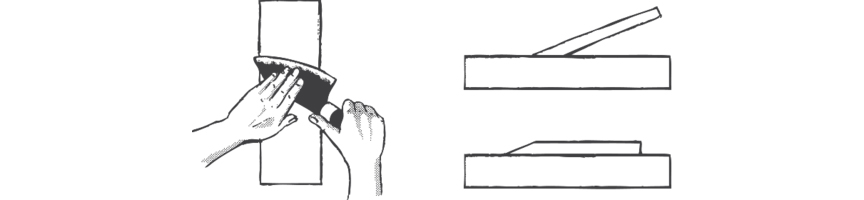

Soak your Whetstone

The whetstone should first be soaked in water for about 10 minutes before using it. Thereafter place on a slip-free surface and ensure the stone is kept slightly wet during the grinding process by dribbling some water on the surface. A towel placed under the whetstone is a good tip to prevent slipping and provide a suitable material to absorb excess water.

Sharpening Double-Bevelled Blades

Grind the knife with a 15° angle to the whetstone, moving the blade with light pressure toward and away from your body. Repeat this process until you can feel a fine burr. Turn over the knife and repeat above for the other side. This should be repeated proportionally on all parts of the blade. It is important to grind both sides of the blade equally to regain a symmetrically sharpened knife. To remove the burr formed along the blade as a result of sharpening, place a piece of newspaper on a flat surface and holding the knife at a similar angle used on the whetstone, swipe the blade sideways left and right across the newspaper. Once the burr is removed, you will feel a smooth edge along the blade. After sharpening carefully wash, dry, and safely store your knife.

Sharpening Single-Bevelled Blades

Place the ground side first on the whetstone. Make sure that you use the angle recommended by the manufacturer. Grind the knife with a 45° angle to the whetstone, moving the blade with light pressure away from and toward your body. Repeat this process until you feel a fine burr. Once the ground side is done, turnover the knife and repeat the process as described above on the hollow-ground side but less often – 1/10 will do. To remove the burr formed along the blade as a result of sharpening, place a piece of newspaper on a flat surface and holding the knife at a similar angle used on the whetstone, swipe the blade sideways left and right across the newspaper. Once the burr is removed, you will only feel a smooth edge along the blade. After sharpening carefully wash, dry, and safely store your knife.

Best Cutting Surface & Technique for your Shun

One aspect of caring for your knives is maintaining the edge and, when needed, sharpening the blade.

But it’s also important to be aware of how you’re using your knives on a daily basis. The cutting surface you are using will directly affect the blade’s edge. A good cutting board will help retain a sharp edge for substantially longer.

Wood, wood composite and polyethene boards are all excellent choices. Tile, ceramic, marble, granite, or any kind of glass cutting boards are poor choices and will dull your blade very quickly.

Shun knives are designed to be used in a smooth, slicing motion – never in an up and down “chopping” manner. Imagine cutting wood with a handsaw, then slicing through your food with a similar motion, intentionally pushing the knife forward and down as you slice, then pulling it back toward your body. Always pay attention to where your fingers are in relation to the knife.

Your skill and experience level should determine the speed at which you cut. When first slicing with a Shun, it’s best to slow down and enjoy the effortless precision and cutting ability of your new knife. Shun knives are intended to be used for precision cutting purposes only – not for stabbing, piercing, or chopping. Use your Shun knives on meats and vegetables only, not on bones or very thick-skinned vegetables.